STEAM bases on the experiences gained in the field of off-shore platform and naval constructions. It always keeps the attention to the construction and yard needs, not only during Construction Engineering activities, but also during the Design which is done, in any case, in a stringent way congruent with Project and Customer’s specifications.

Transports, Heavy Lifting and Loadouts

In team with the Client, STEAM defines and finalizes:

-Systems and details for any type of transport/transfer inside/outside the yard.

-Systems, details and structural verifications, also with FEM Analysis, for every Heavy Lifting.

-Load-outs of any type.

STEAM S.r.l. has obtained ISO 9001 Certification for the Design activities related to the «Special Handling, Liftings and Transportations»

Marine Transport – Grillage and Sea-Fastening Design

In team with the Client STEAM defines, designs and details, according to the “Certification Body” Requirements:

-Barge selection

-Marine Transport Conditions

-Grillage and Sea Fastening Design

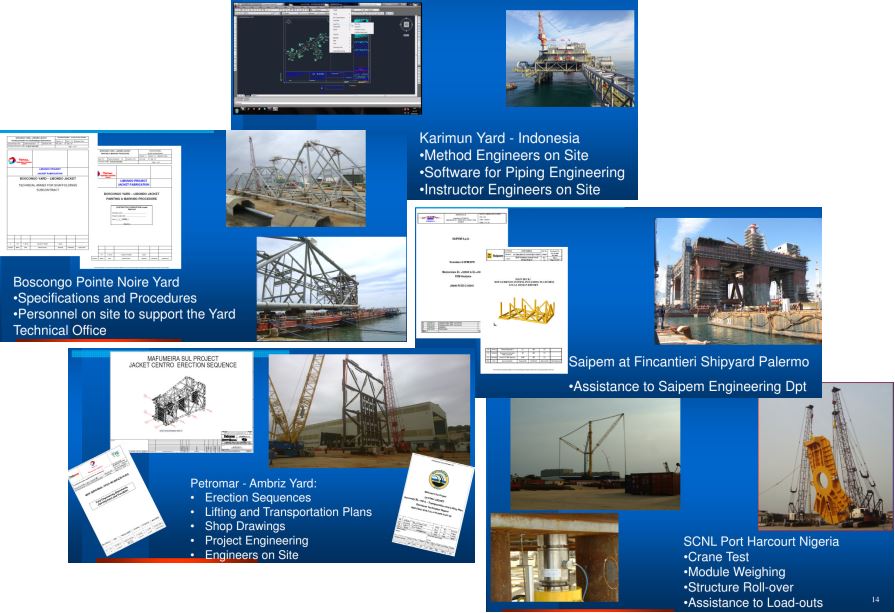

Construction Yards Support

STEAM provides for personnel to support Construction Yards.

-Saipem Construction Nigeria Ltd (Port Harcourt – Nigeria)

-Saipem at Fincantieri shipyard (Palermo – Italy)

-BosCongo (Point Noire – Congo)

-PT Saipem (Karimun – Indonesia)

-PT Hanjung (in behalf of Saipem) (Indonesia)

-Petromar Yard (Ambriz – Angola)

-Saipem do Brasil Yard (Guarujà – Brasil)

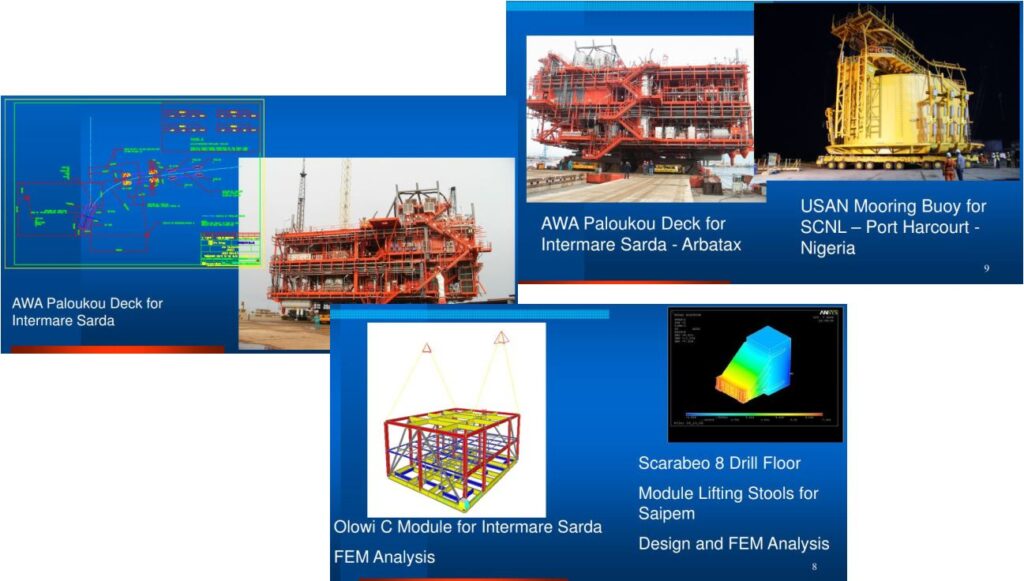

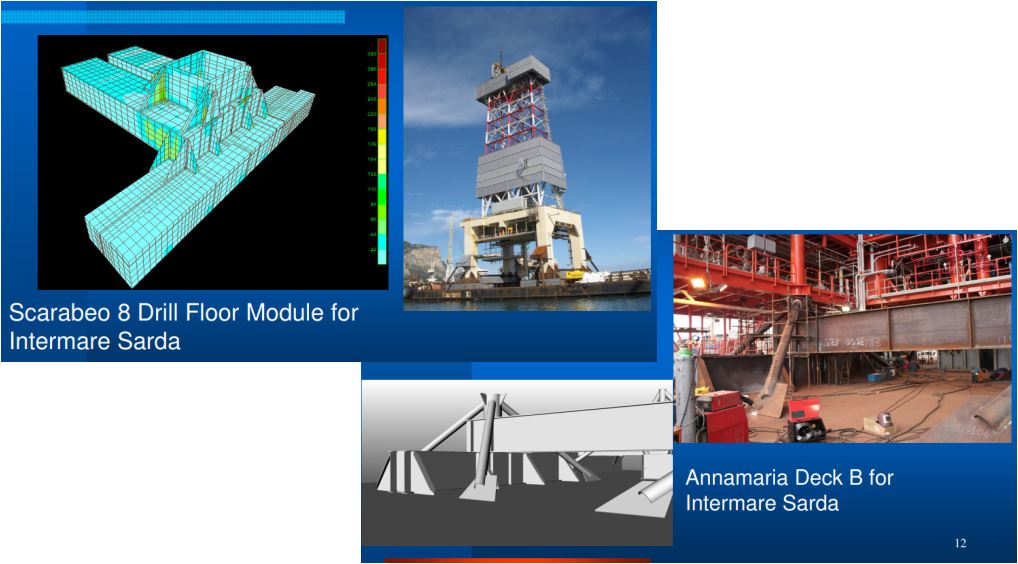

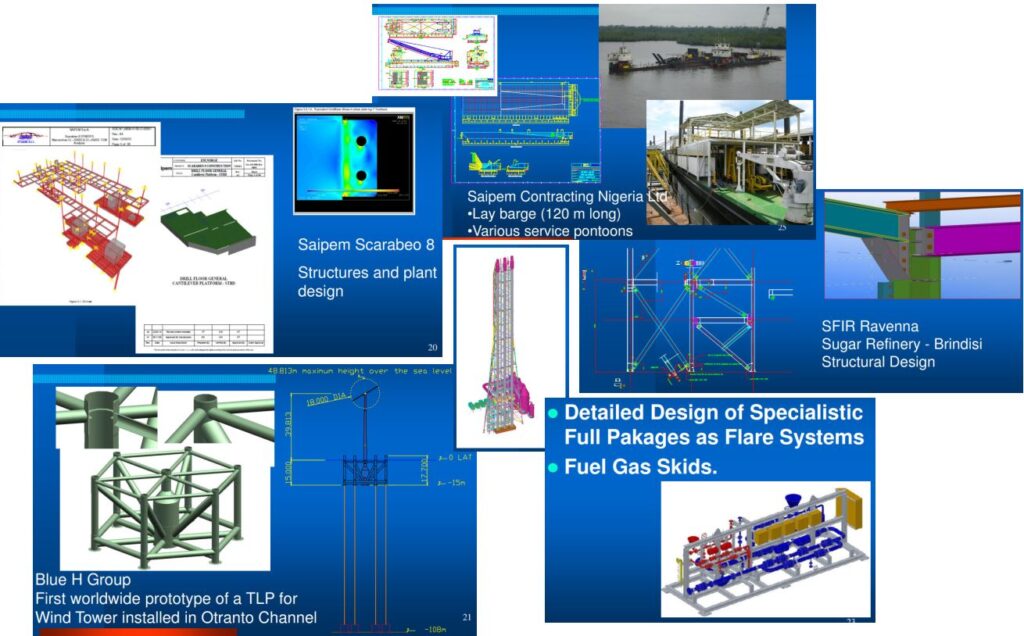

Structural Design

STEAM provides for design of offshore platforms, onshore plants and naval engineering.

The “fabricator/constructor point of view” is always present in all design steps.

The Design is based on the “fit for purpose” criteria.

STEAM has obtained ISO 9001 Certification for Steel Structural Design.

Onshore Plant Design

STEAM has the competence to develop the design of the onshore plants such as:

Machinery Specifications, Tanks and piping design according to the main international Rules,

Detailed Design of Specialistic Full Pakages as Flare Systems, Fuel Gas Skids.

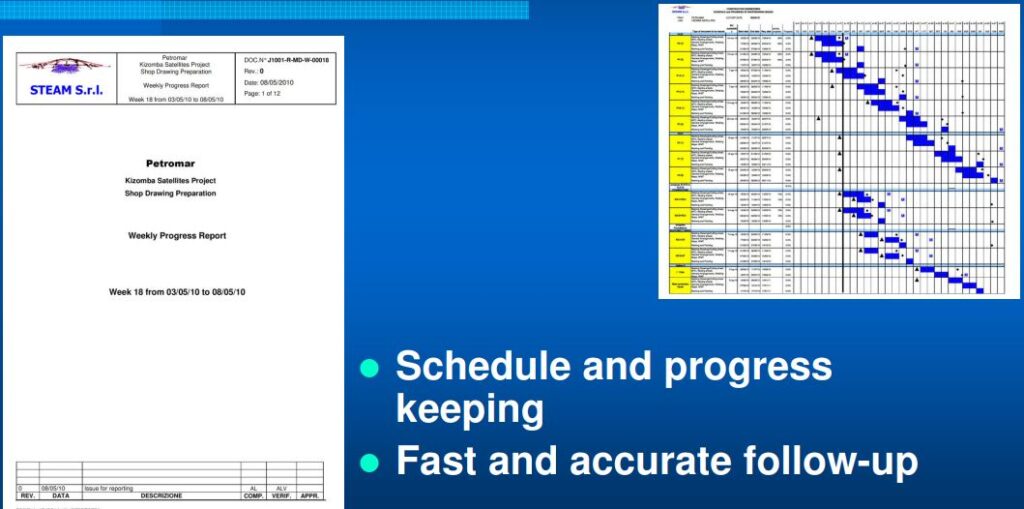

Shop Drawing Preparation

STEAM has a long experience in the shop drawing preparation coming from the one got through its management in previous activities. Steam mainly manages the 3D models (Tekla, Rhino, and Inventor) to produce the shopdrawings according to the Client needs and the production equipments to be used.

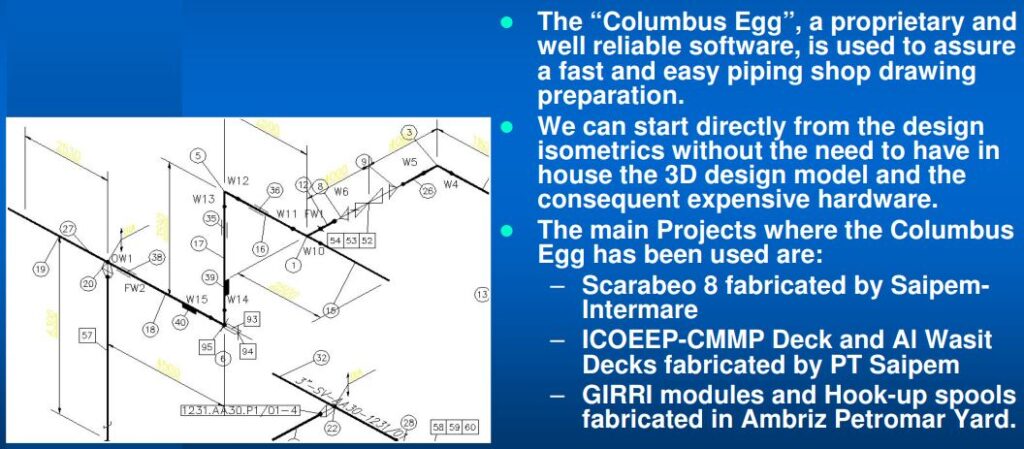

Isometric Shop Drawing Preparation

The “Columbus Egg”, a proprietary and well reliable software, is used to assure a fast and easy piping shop drawing preparation. We can start directly from the design isometrics without the need to have in house the 3D design model and the consequent expensive hardware.

The main Projects where the Columbus Egg has been used are:

-Scarabeo 8 fabricated by Saipem-Intermare

-ICOEEP-CMMP Deck and Al Wasit Decks fabricated by PT Saipem

-GIRRI modules and Hook-up spools fabricated in Ambriz Petromar Yard.